1959 - The first steam cleaner

Oskar Ehrle develops and constructs the first DR 600 steam jet on behalf of the company "WAP - Guido Oberdorfer".

Today, EHRLE is one of the world’s leading providers of innovative solutions in the field of high-pressure cleaning technology and vehicle washing. Since its foundation, the company has attached great importance to sophisticated technology, innovative ideas, first-class quality and excellent service. EHRLE products are characterized by their above-average product quality and technology and impress with their modern design, high-quality materials, long service life and outstanding economy.

Through continuous new product developments and further developments, EHRLE has achieved a high manufacturing standard which has enabled the worldwide success of its products. Made by EHRLE stands for top German quality worldwide. Thanks to many years of experience and highly motivated, qualified employees, the company can guarantee production at the highest quality level in all areas of the company.

Anton Ehrle was born in Voggenreute in 1894. He learns the blacksmith’s trade and passes his master craftsman’s examination in 1927. It is he who introduces metalworking to the family. As early as 1959, he developed and designed the first steam cleaner for the WAP company – the DR 600.

In 1922, Oskar Ehrle, the founder of today’s EHRLE company, was born in Bad Schussenried as the eldest of five siblings. After attending elementary school, he completed an apprenticeship as a hand molder from 1936 to 1939. During the Second World War, he was drafted as a pilot of rescue planes. In 1945, he was taken prisoner of war by the Russians in Werche-Tura in Siberia and only returned to his home town at the end of 1947, suffering from hunger and illness.

Reiner Ehrle was born in Illertissen in 1959. After attending elementary school, he first graduated from secondary school with a “Mittlere Reife”, before leaving the technical college in Neu-Ulm in 1977 with a “Fachabitur”. After an internship in the United States in 1978, he studied mechanical engineering at the University of Applied Sciences in Ulm from 1979 to 1983, graduating with a degree in mechanical engineering.

Oskar Ehrle develops and constructs the first DR 600 steam jet on behalf of the company "WAP - Guido Oberdorfer".

The Ehrle company is founded. A factory building is erected in Herbststraße (today Thomas-Mann-Straße) in Illertissen.

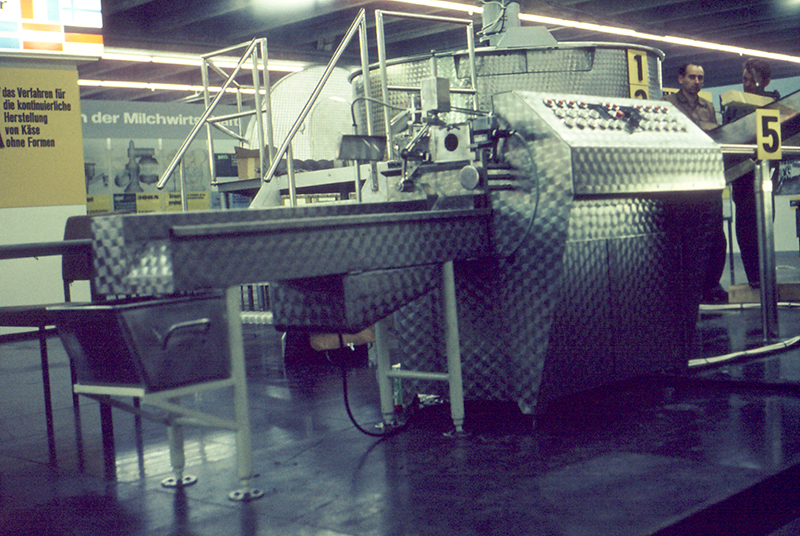

EHRLE develops and constructs a fully automatic cheese cutter with salt spray system on behalf of Werner & Pfleiderer (Stuttgart).

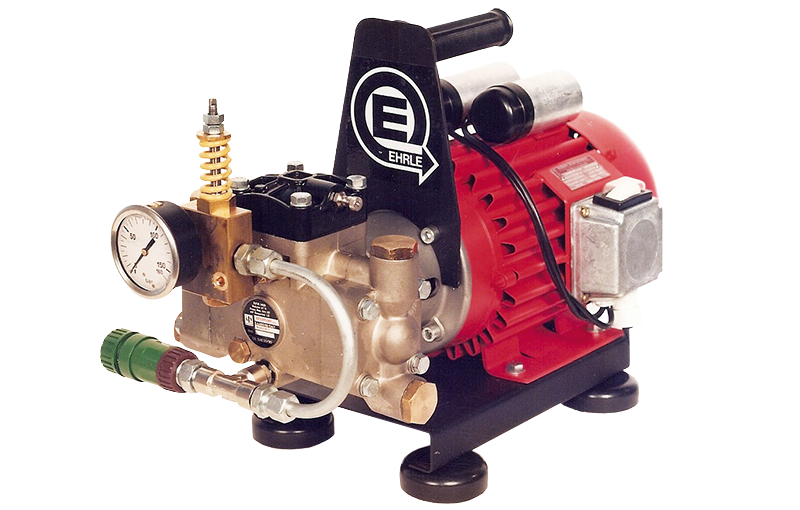

Start of series production of the EHRLE Jet 750 steam blaster, using a single-piston pump designed by Oskar Ehrle.

With the further development of high-pressure pumps, the first cold water high-pressure cleaners are produced in series.

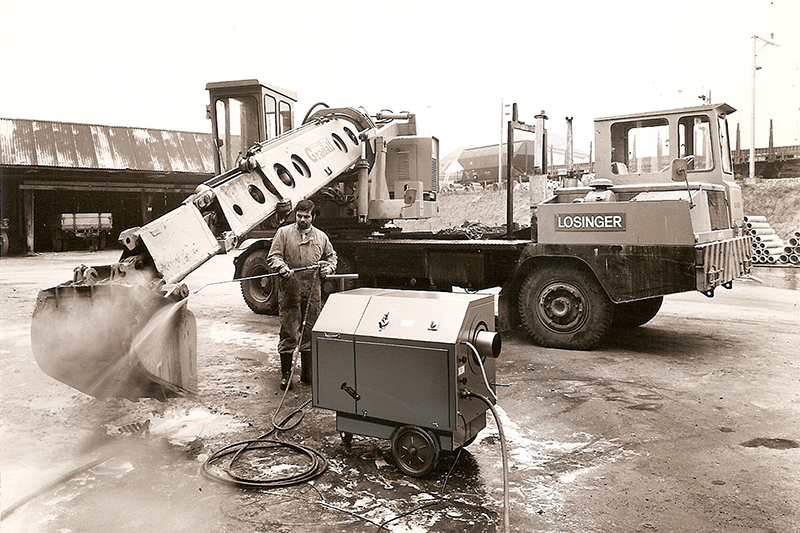

The first EHRLE HDW 750 hot water high-pressure cleaner goes into production. This device marks the transition from steam jet cleaners to the hot water high-pressure cleaners we know today.

The first general agency in Switzerland is awarded. The new hot water high-pressure cleaners are increasingly used in many industries and enjoy great popularity.

A water heater for swimming pools with a horizontal heat exchanger, “Iller Thermal”, is developed and designed.

Further development and model change of the hot water high-pressure cleaners. Various accessories with combined high-pressure and steam nozzles and surface washing brushes are introduced to the market.

Model update for the hot water high-pressure cleaners. The push handle has been replaced by a swivel castor with a push bar. The model range has been expanded to include powerful appliances with a water output of up to 1,800 l/h.

Development and construction of the first self-service car wash with water softening and heating system as the forerunner of today's self-service car wash systems. This laid the foundation for the company's continued success.

Further development and model change for hot water high-pressure cleaners. Various accessories for high-pressure cleaners are developed and launched on the market. The new company color RED is introduced.

Development, design and manufacture of the first consumer cold water high-pressure cleaner. These appliances are sold in specialist stores at home and abroad with great success.

Model change in the area of hot water high-pressure cleaners. Modern CNC-controlled machine tools were used for series production for the first time.

EHRLE becomes a complete supplier of modern self-service car wash systems. For the first time, customers are offered prefabricated car wash panels and our own steel structures for car washes.

There is another model change in the hot water high-pressure cleaner range. Transparent tanks and a plastic appliance cover are being used for the first time.

For the first time, the devices are produced on a semi-automatic production line

The first stationary high-pressure cleaner in the cold water range is designed and developed.

Due to the market success, stationary hot water high-pressure cleaners are also introduced. The customer and application areas are permanently expanded.

Model change for cold water high-pressure cleaners. Modern triplex piston pumps with pressure up to 200 bar and plastic appliance hoods are introduced.

Design and manufacture of hot water high-pressure cleaners with combustion engines. This means that the high-pressure cleaner is now independent of electricity and can be used anywhere.

Following a successful breakthrough at international level in the CarWash Outdoor sector, multi-user systems with up to twelve wash bays are now available.

The entire technology is housed centrally in a BetonTechnik container between the wash bays.

Model change and new design for cold water high-pressure cleaners in the consumer sector.

The ETRONIC I control system is introduced. All appliance functions are now monitored and evaluated electronically.

The stationary hot water high-pressure cleaners are also getting a facelift: the appliances are now available in complete stainless steel housings.

EHRLE develops the “Design Pro” steel construction for CarWash SB systems. The design, which is protected by design patent, becomes the EHRLE trademark.

Production of the self-service vacuum cleaners in housings made of powder-coated sheet steel or stainless steel. The special feature is the overhead guidance of the suction hose, which makes it easy for the customer to handle.

The JetWash and JetWash Plus self-service car wash systems are introduced to round off the range. This solution is particularly suitable for systems at petrol stations or garages.

Introduction of the ETRONIC II control system, which offers advantages in the operation and maintenance of the machines.

Sales launch of vacuum sweepers for commercial use. These machines are available in various performance classes and also as ride-on machines. They are powered electrically or by a combustion engine.

Start of production of the SmartWash and SmartWash Plus modules. These single-bay self-service car washes offer a professional and cost-effective alternative, especially for petrol stations with an integrated wash bay.

Entry into the sale of EHRPORT gantry car washes for cars. These automatic car wash systems serve as a supplement to the self-service car wash systems, where customers want to decide for themselves how they want to wash their cars.

The first complete wash and care center becomes reality. The EHRLE “Design Pro” steel construction combines self-service wash bays and automatic gantry car washes.

The KD 2x2 cold water high-pressure cleaner is the two-wheeled, more compact version of the KD 4x4.

In 2016, a special rim cleaning chemical was introduced that was specifically developed to remove stubborn dirt such as brake dust and grime. These chemical cleaning agents are effective, gentle on the rims and contribute to the optimal care and maintenance of vehicle rims.

Introduction of the food class. High-pressure cleaners specially manufactured for the food sector, which are characterized by their tyres and stainless steel components.

The Etronic II high-pressure cleaner, which was launched in 2019, is characterized by its powerful cleaning technology and user-friendly controls. The new device control allows users to work more efficiently and significantly improve cleaning results.

The new steel construction wash hero has been developed and offers a robust, durable construction. It supports the load-bearing structure and ensures stability and weather resistance in modern washing systems.

In 2021, the new KD2x2 high-pressure cleaner was launched, featuring an improved chassis and a more powerful pump. These innovations ensure increased durability and more efficient cleaning performance, making the KD2x2 ideal for demanding applications.

In 2022, the KS device, a wall-mounted high-pressure cleaner system, was introduced together with a new mat cleaner. The KS device enables space-saving installation, while the mat cleaner offers effective and gentle cleaning of vehicle mats.

In 2023, an innovative heat pump for self-service car washes was introduced, which enables energy-efficient water heating. This technology not only improves the cleaning quality, but also significantly reduces the energy consumption and operating costs of the car washes.

In 2024, the MultiTerminal was introduced, which combines four powerful components for self-service car washes. It consists of self-service vacuum cleaners, self-service Tornado cleaning nozzles with integrated detergent dosing, self-service compressed air guns with 3 bar pressure and electric self-service tire inflation stations that offer comprehensive cleaning and care for vehicles.

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information